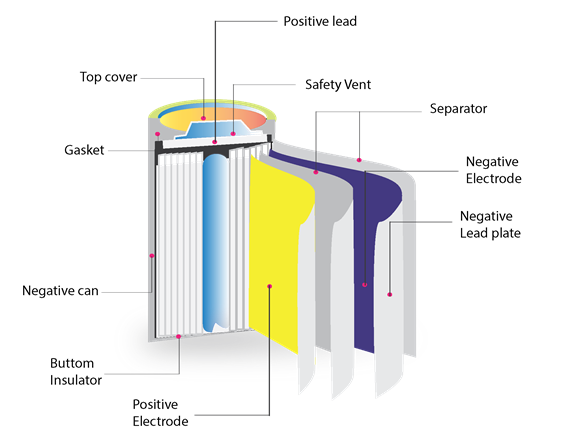

Lithium cell

Step 1 Electrode Sheet Preparation

- Furnace: raw active material (Cathode & Anode)

- Milling Machine: grind & normalize the sintered material

- Mixer: mix active, conductive, and binder material into slurry under vacuum

- Coater: apply layer(s) of slurry onto current collector and dry it with an attached heater

- Rolling Press (calendar): compress the electrode to a desired thickness/density

Step 2 Cell Assembly

Winding Method

- Slitting Machine: slit/cut electrode sheet to strips of desired size

- Ultrasonic Welding Machine: joining of multi-layer electrodes, and/or tabs to collectors

- Winding Machine: form layers of Anode, Separator, and Cathode into a cell core

- Short-circuit Detector: test for integrity of the cell

- Vacuum Oven: remove any moister within the cell

Step 3 Case Sealing

- Spot Welding Machine: allow contact to be made from cell to bottom of case (grounding)

- Grooving machine: create indent on the neck of case to allow for proper seal (after inserting the cell core)

- Welding Machine: attach cell to cap (positive)

- Electrolyte Filling: inject the case with electrolyte under suitable environment within glove box

- Sealing Machine (Crimper): align cap with the open end of case and seal case inside glove box under suitable environment

- Recommend: wrap the newly finished battery with heat-shrinkable PVC for isolation of positive and negative terminals

- Battery Analyzer: charge/discharge the assembled battery for cell activation

Step 4 Battery Testing

Battery Analyzer to test the battery’s performance and Resistance Tester to measure battery’s internal resistance

Electric Vehicle and EV Lithium-ion Battery Training Courses

EV EVSE Business Management Course for Entrepreneurs

This Techno Commercial course: Throughout this training session, AEVT bridges the needs of startups so that candidate can understand the technology from basic of EV to EVSE equipment like Lithium-ion battery, Battery pack assembly process, EV Motor, Charger, charging station development and all others parts/ equipment's calculation, selection, building a Legal Foundation, Understanding Finance Basics, Business Planning and Fundraising.

Lithium Battery Pack Assembly course will cover li-ion cell to battery characteristic's, different parameters, EV battery Pack design aspect, calculation, assembly line unit detailing with financial aspects ,govt guidelines ,policies etc.